Special Grade Composite Hoses

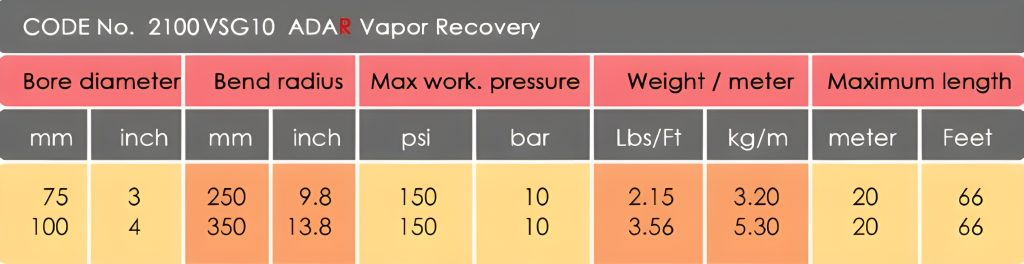

CODE No. 2100 VSG10 Vapor Recovery

Inner wire

Linnig

Outer Cover

Colour Code

Outer Wire

Working Pressure

Max.Elongation

Maximim Twist

Vacuum Range

Elect.resistance

: Stainless steel

: PP Fabric

: PVC Coated Fabric

: Yellow with White stripe

: Galvanised steel

: 10 Bar

: 10% on proof pressure

: 10°/mtr

: 0.9 bar

: 2.5 Ohms/mtr<2″ Hose 1.0 Ohms/mtr>2″Hose

DESCRIPTION

Composite hose has a spiral internal and external metal supporting wire which can be galvanized steel, stainless steel or polypropylene coated steel. In between the wires there are polypropylene fabrics and films with an abrasion resistant PVC coated fabric cover. The hose contains a barrier layer for 100% aromatic hydrocarbons

PRINCIPAL APPLICATIONS

Vapor Recovery hoses are designed the recovery of volatile hydrocarbon vapors in rail car and truck loading terminals, and unloading at service stations. Designed for compliance with EPA stage-1 requirements for recovering volatile hydrocarbon vapors in rail car or tank truck loading at bulk terminals,and unloading at service stations.Designed to meet the demands for light weight, flexiility and strenght imposed on these hoses in the marine environment in vapor recovery operations.

Designed to meet USCG requirement for recovering certains chemical and volatile hydrocarbon vapors during ship and barge loading at bulkstorage terminals, plants,refineries and others transfer operation in a marine environment Chemical and hydrocarbon vapors and 100% aromatics 4:1 Safety Factor, ISO Approved.

CLASSIFICATION

Fuel and Oil Group 1 Hose

COLOUR CODE

Black color with white strip

MANUFACTURE

Manufactured to the specification where applicable to EN 13765:2018,BS5842:1980 & USCG, IMO,ECH, IBC Codes and Regulations-Type 2

TEMPERATURE

Depending on the conveyant -30°C to+80°C refer to Chemical Compatibilty Chart

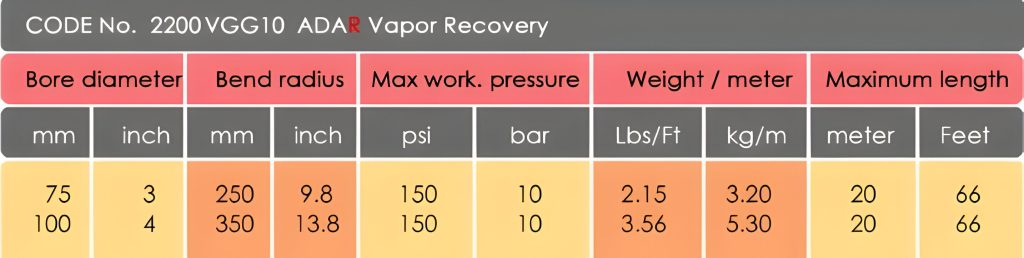

CODE No. 2200 VGG10 Vapor Recovery

Inner wire

Linnig

Outer Cover

Colour Code

Outer Wire

Working Pressure

Max.Elongation

Maximim Twist

Vacuum Range

Elect.resistance

: Galvanised steel

: PP Fabric

: PVC Coated Fabric

: Yellow with White stripe

: Galvanised steel

: 10 Bar

: 10% on proof pressure

: 10°/mtr

: 0.9 bar

: 2.5 Ohms/mtr<2″ Hose 1.0 Ohms/mtr>2″Hose

DESCRIPTION

Composite hose has a spiral internal and external metal supporting wire which can be galvanized steel, stainless steel or polypropylene coated steel. In between the wires there are polypropylene fabrics and films with an abrasion resistant PVC coated fabric cover. The hose contains a barrier layer for 100% aromatic hydrocarbons.

PRINCIPAL APPLICATIONS

Vapor Recovery hoses are designed the recovery of volatile hydrocarbon vapors in rail car and truck loading terminals, and unloading at service stations. Designed for compliance with EPA stage-1 requirements for recovering volatile hydrocarbon vapors in rail car or tank truck loading at bulk terminals,and unloading at service stations.Designed to meet the demands for light weight, flexiility and strenght imposed on these hoses in the marine environment in vapor recovery operations.

Designed to meet USCG requirement for recovering certains chemical and volatile hydrocarbon vapors during ship and barge loading at bulkstorage terminals, plants,refineries and others transfer operation in a marine environment Chemical and hydrocarbon vapors and 100% aromatics 4:1 Safety Factor, ISO Approved.

CLASSIFICATION

Fuel and Oil Group 1 Hose

COLOUR CODE

Yellow color with White strip

MANUFACTURE

Manufactured to the specification where applicable to EN 13765:2018,BS5842:1980 & USCG, IMO,ECH, IBC Codes and Regulations-Type 2

TEMPERATURE

Depending on the conveyant -30°C to+80°C refer to Chemical Compatibilty Chart

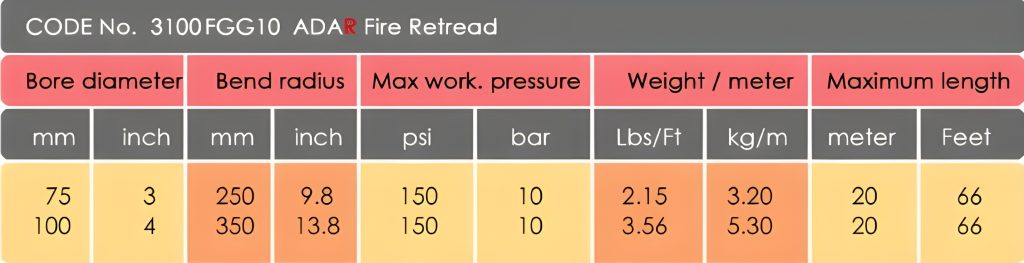

CODE No. 3100 FGG10 Fire Resread

Inner wire

Linnig

Outer Cover

Colour Code

Outer Wire

Working Pressure

Max.Elongation

Maximim Twist

Vacuum Range

Elect.resistance

: Galvanised steel

: PP Fabric

: PVC Coated impregnate Fabric

: Orange with Yellow stripe

: Galvanised steel

: 10 Bar

: 10% on proof pressure

: 10°/mtr

: 0.9 bar

: 2.5 Ohms/mtr<2″ Hose 1.0 Ohms/mtr>2″Hose

DESCRIPTION

Composite hose has a spiral internal and external metal supporting wire which can be galvanized steel, stainless steel or polypropylene coated steel. In between the wires there are polypropylene fabrics and films with an abrasion resistant PVC coated fabric cover. The hose contains a barrier layer for 100% aromatic hydrocarbons.

PRINCIPAL APPLICATIONS

Fire Retread hoses are designed for a wide range of fuel, oil and lubricant applications where lightweight and flexbility are essential, i.e rail car and tank truck loading and delivery, storage tank transfer, refinery process, drumming, manifloding batching, and blending. 4:1 Safety Factor, ISO Approved

CLASSIFICATION

Fuel and Oil Group 1 Hose

COLOUR CODE

Orange color with yellow strip

MANUFACTURE

Manufactured to the specification where applicable to EN 13765:2018,BS5842:1980 & USCG, IMO,ECH, IBC Codes and Regulations-Type 2

TEMPERATURE

Depending on the conveyant -30°C to+80°C refer to Chemical Compatibilty Chart

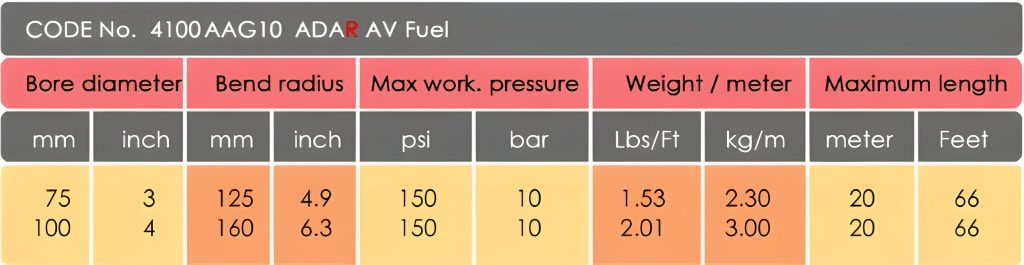

CODE No. 4100 AGG10 AV Fuel

Inner wire

Linnig

Outer Cover

Colour Code

Outer Wire

Working Pressure

Max.Elongation

Maximim Twist

Vacuum Range

Elect.resistance

: Aluminium wire

: PP Fabric

: PVC Coated Fabric

: Black with White stripe

: Galvanised steel

: 10 Bar

: 10% on proof pressure

: 10°/mtr

: 0.9 bar

: 2.5 Ohms/mtr<2″ Hose 1.0 Ohms/mtr>2″Hose

DESCRIPTION

Composite hose has a spiral internal and external metal supporting wire which can be galvanized steel, stainless steel or polypropylene coated steel. In between the wires there are polypropylene fabrics and films with an abrasion resistant PVC coated fabric cover. The hose contains a barrier layer for 100% aromatic hydrocarbons.

PRINCIPAL APPLICATIONS

Aviation Fuel Light hoses are designed for the weight of the hose is critical, however the crush resistance is not as good as for AV Fuel For use in the aviation industry for the conveyance of aviation fuels.4:1 Safety Factor ISO Approved

CLASSIFICATION

Fuel and Oil Group 1 Hose

COLOUR CODE

Black color with white strip

MANUFACTURE

Manufactured to the specification where applicable to EN 13765:2018,BS5842:1980 & USCG, IMO,ECH, IBC Codes and Regulations-Type 2

TEMPERATURE

Depending on the conveyant -30°C to+80°C refer to Chemical Compatibilty Chart

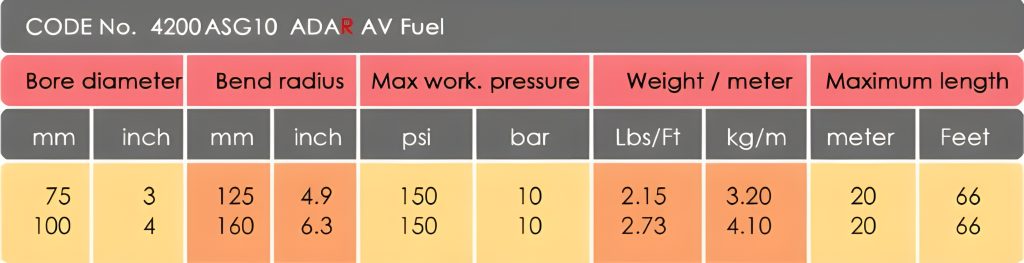

CODE No. 4200 ASG10 AV Fuel

Inner wire

Linnig

Outer Cover

Colour Code

Outer Wire

Working Pressure

Max.Elongation

Maximim Twist

Vacuum Range

Elect.resistance

: Aluminium wire

: PP Fabric

: PVC Coated Fabric

: Black with White stripe

: Galvanised steel

: 10 Bar

: 10% on proof pressure

: 10°/mtr

: 0.9 bar

: 2.5 Ohms/mtr<2″ Hose 1.0 Ohms/mtr>2″Hose

DESCRIPTION

Composite hose has a spiral internal and external metal supporting wire which can be galvanized steel, stainless steel or polypropylene coated steel. In between the wires there are polypropylene fabrics and films with an abrasion resistant PVC coated fabric cover. The hose contains a barrier layer for 100% aromatic hydrocarbons.

PRINCIPAL APPLICATIONS

Aviation Fuel hoses are designed for the weight of the hose is critical, however the crush resistance is not as good as for AV Fuel For use in the aviation industry for the conveyance of aviation fuels.4:1 Safety Factor ISO Approved

CLASSIFICATION

Fuel and Oil Group 1 Hose

COLOUR CODE

Black color with white strip

MANUFACTURE

Manufactured to the specification where applicable to EN 13765:2018,BS5842:1980 & USCG, IMO,ECH, IBC Codes and Regulations-Type 2

TEMPERATURE

Depending on the conveyant -30°C to+80°C refer to Chemical Compatibilty Chart