Technology

COMPOSITE HOSE

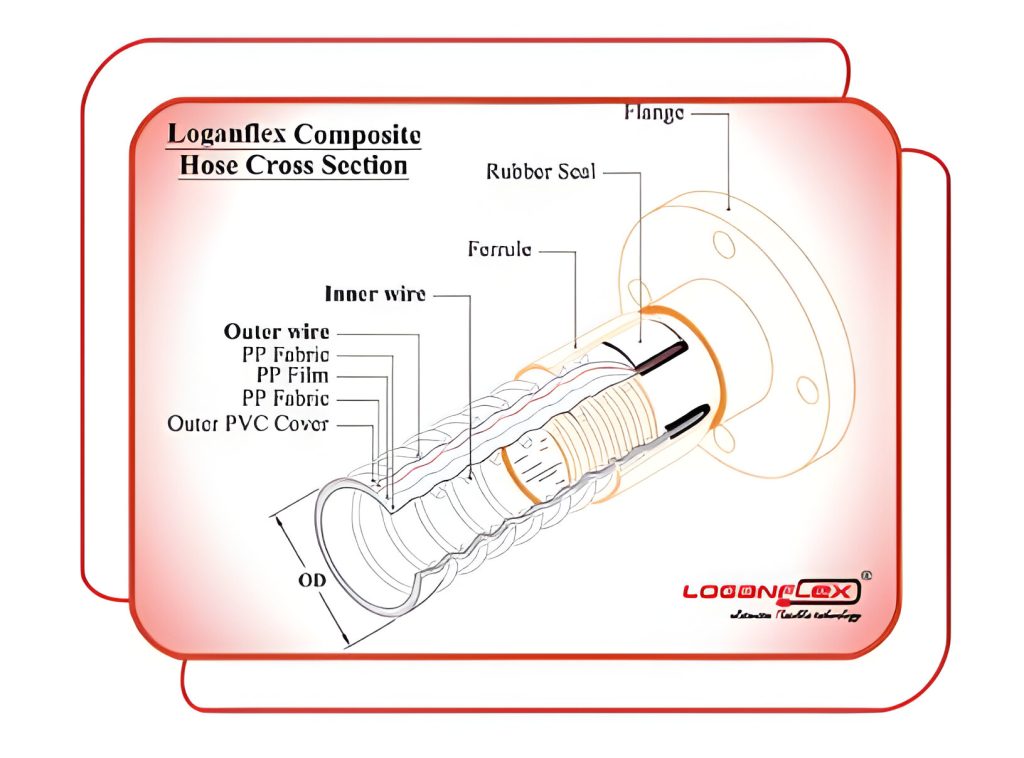

Composite Hoses can provide the vital flexible connection to compensate for vibration, movement or misalignment in a fluid transfer system. Composite hose has a spiral internal metal supporting wire which can be galvanized steel, stainless steel, aluminium or polypropylene coated steel with a spiral external wire which is generally galvanized or stainless steel in between the wires there are layers of thermoplastic fabrics and film. The diameters of hoses, we produce in 25 meter lengths with diameter of 25mm 38mm, 50mm, 65mm, 75mm,100mm,150mm, 200mm. The temperature range of our hoses is -30"c to +80"c. LOGANFLEX hoses having working pressure of 7bar, 10bar and 14bar Working Pressure

LOGANFLEX brand chemical hoses are designed for suction and discharge of a wide range of chemicals and acids alkalis and much more

THE FUNCTIONS OF THE VARIOUS COMPONENTS ARE BASICALLY AS FOLLOW

Internal wire sprial support the hose wall and provides resistance to vacuum for suction applications.

External wire sprial armors the hoses against abrasion and impact damage and binds the layers of fabrics and films tightly together

Fabric layers act as strenght members against internal pressure. It is also a common feature of many composite hoses to have as the external layer PVC coated fabric.This provides an easily cleanable color coded surface and gives additional abrasion resistance.

Film layers act as a sealing medium to ensure that no product escapes from the hose. Flims and fabrics can be polypropylene, polyamide, PTFE, polyester polyaramid or glass, By combining theses alternatives components in various ways it is possible to produce hoses with a wide range of chemical resistance, working temperature and pressure

End fittings as with all types, composite hose assembly depends on the strength and reliability of its coupling system. LOGANFLEX has developed its own unique fitting configuration and swaging system, which uses high quality rubber seals, steel or stainless steel ferrules and coupling to ensure that when prototype tests conducted, the hose will burst before the end fitting is expelled.

This ensures the maximum strenght of the hose is fully achieved.Our swaging system gives superior results to wire whipping or clamping methods of attachment, and guarantees electrical continunity to ensure static eletricity is fully discharged.

COMPOSITE HOSE

PRINCIPLE OF COMPOSITE HOSES

The Flexible Composite hoses are used for below mentioned application & industries:

- Fuels & oils

- Dry Chemicals

- Fluids

- Industrial Gases

- Industries

- Petroleum & Gas Industries

- Chemical Industries

- Ship to shore

DESCRIPTION OF COMPOSITE HOSES

LOGANFLEX brand chemical hoses are designed for suction and discharge of a wide range of chemicals and acids alkalis and much more

LOGANFLEX brand oil hoses can be used for road tanker loading and offloading in plant applications were a robust flexible hose is required with a proven safety record

LOGANFLEX brand lightweight fuel hoses are designed for suction and discharge of leaded & inleaded petrol, diesel, fuel oils, hydrocarbon with 100% aromatic content and aviation spirit

ADVANTAGE OF COMPOSITE HOSES

- Better life(Avg.life 18months to 36months).

- Lower in weight than rubber hoses and much lesser than ss hoses

- Flexible,so easier maneuvering and handling

- Fatigue free & less ageing compare to rubber hoses

- Made up of layers that resists the chemicals & maintains maximum strenght,durability,e Flexibilty and compatibility with range of chemicals

- Having protection from corrosion and attack by other liquids, UV Radiation and ozone by their tought,PVC-impregnated fabric covers

- Meets the eletrical continuity requirements for industrial application

- Temperature tolerance from -30°c to +80°c.

Does not contaminate the fluid like clean fuel/oil while transferring.In other words,the original quality of liquid remains same while transferring

COMPARSION

COMPOSITE HOSE VS RUBBER HOSE COMPARISON

- Composite hoses are unto 30% lighter than rubber hoses

- The materials used in composite hoses are fatigue free and do not degrade like rubber

- The fluid passing through rubber hoses may be contaminated by the tiny particles of rubber whereas in composite hose the inner layers is polypropylene fabric which will not contaminate the fluid

- The composite hose can be given in different color for different applications so that the hoses dedicated for a particular application can be easily identifed.

- Composite hoses on an average have a longer life than rubber hose

- Eletrical continuinty is maintained throughout the life of the composite hose.

BRAND

LOGANFLEX BRAND

- TRAN FUEL - Used for petro fuel

- TRAN MARINE OIL - Used for black oil

- TRAN CHEM - Used for chemicals

- TRAN MARINE CHEM-Used for chemicals

- TRAN CHEM-PTFE - Used for acids & alkalines

- TRAN VRH- Used in chemical & paint Ind.

INSPECTION, TESTING AND MAINTENANCE OF COMPOSITE HOSES

Visual inspection - check hoses before each operation and before conducting hydrostatic test...

Visual inspection should note :

- Dents ( collapsed or crushed places ) or kinks in hosoes

- Breaks in outer reinforcung wire

- Displacement of inner and outer reinforcing wires from normal pitch

- Displacement of end fitting and signs of fitting leakage

- Wear or damage to end fittings

- Chemicals attack,deterrioration and physical damage to outer cover and car

Moderate abrasion to the outer cover is acceptable if reinforcing fabrics below the cover are undamaged

NOTE :More throught inspection at least every 6 monthes

CAUTION : Hoses with significant defects of the above the types be retired from service

Hydroststic testing - annually or more trequently

Hoses should be tested as follows :

- Drain and thoroughly clea hose per recommended procedure.

- Test eletrical continuinty per recommended procedure

- Inspect hoses visually per recommened procedure.Lay hose straight out on supports or roller bed that allows free movements under pressure

- Blank off ends, Fill hoses completely eith water.Make sure trapped air is released by tilting slighty at one end

- Pressurize assembly to 1-1/2 times the maximum working pressure

- Hold at this pressure and examine for leack

- Test electrial continutty while under pressure.It should be same asfor umpressurzed hose

- Relese pressure-carefully! Drain hoses

- Test for eletrical continuinty upon copletion of pressure test

NOTE :thermoplatice hoses elongate under pressure compared to rubber hose.Elongation under pressure is not an indication of hoses condition or failure of reinforecements

CAUTION : Do not test hoses that fail visual inspection

Electrcal continuinty test - every 6 months or more trequently

To check elctrical continuinty :

- Lay hose flat on ground

-

Check eletrical conitiniuity with battery / bulb continuinty indicator or with ohm meter

(resistance should be 10 ohms or less).

NOTE : Hoses that are not electrically continuous should be retired from service

CAUTION : Hoses that are not electrically continuous present a significant sparking or internal arc over hazard

Cleaning -after use or prolonged storage, before testing......

Most appropriate cleaning method depends on use and locations

- Thoroughly drain strong acid conveyants, or other reactive conveyants,before cleaning to avoid exothemic reactions.

- Electrially ground hose during cleaning to avoid static charge build-up-especially in the presense of flammable liquids or vapors.

- Flesh with fluids like fresh or sea water,hot water,detergents,common solvents at ambient temperatures.

- Ddrain thoroughly after flushing, especially, if sea water is used, to minimize inner wire and fittings corrosion

- Fully drain of any cleaning fluids / solvent to avoid any chemical reactions when hose is put back in service.

Loose steam or compressed air may be used to clean hoses

- Drain and thoroughly clea hose per recommended procedure.

- Test eletrical continuinty per recommended procedure

- Inspect hoses visually per recommened procedure.Lay hose straight out on supports or roller bed that allows free movements under pressure

- Blank off ends, Fill hoses completely eith water.Make sure trapped air is released by tilting slighty at one end

- Pressurize assembly to 1-1/2 times the maximum working pressure

- Hold at this pressure and examine for leack

- Test electrial continutty while under pressure.It should be same asfor umpressurzed hose

- Relese pressure-carefully! Drain hoses

- Test for eletrical continuinty upon copletion of pressure test

NOTE :thermoplatice hoses elongate under pressure compared to rubber hose.Elongation under pressure is not an indication of hoses condition or failure of reinforecements

CAUTION : Do not test hoses that fail visual inspection

Hose repairs - consult accord international ,Inc

Depending on overall condition,it may be possible to repair hoses damaged in service. The repair of poly-propylene hoses requires specialized knowledge and procedures.

Note : All repairs should be undertaken by trained and authorized personnel

CARE & MAINTENANCE